CORSEMP system

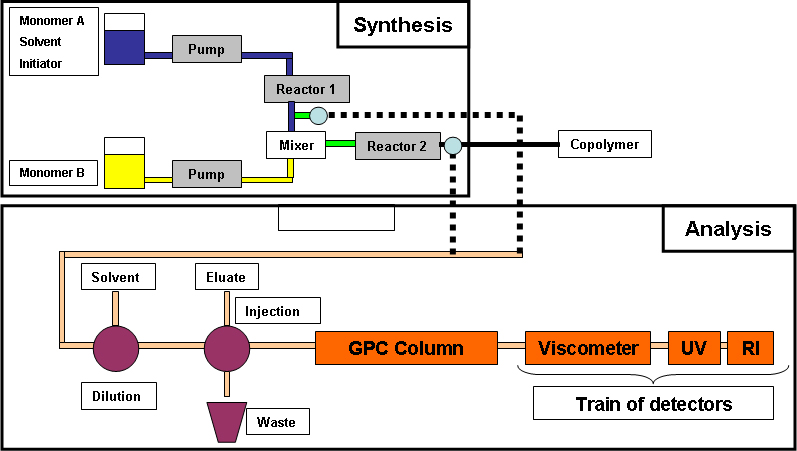

We have developed a new method for online characterization of polymers, termed Continuous Online Rapid Size-Exclusion chromatography Monitoring of Polymerizations (CORSEMP). It consists in automatic samplings, dilutions and injections of polymers synthesized in continuous flow. The system allows molecular weight and molecular weight distribution of polymers to be ‘real-time’ monitored by means of a chromatographic column. This technique is well adapted to assess the effects of stepwise modifications of operating conditions over the dynamics of the reactor by running High Throughput Experiments and shows itself a convenient tool for polymer library synthesis.

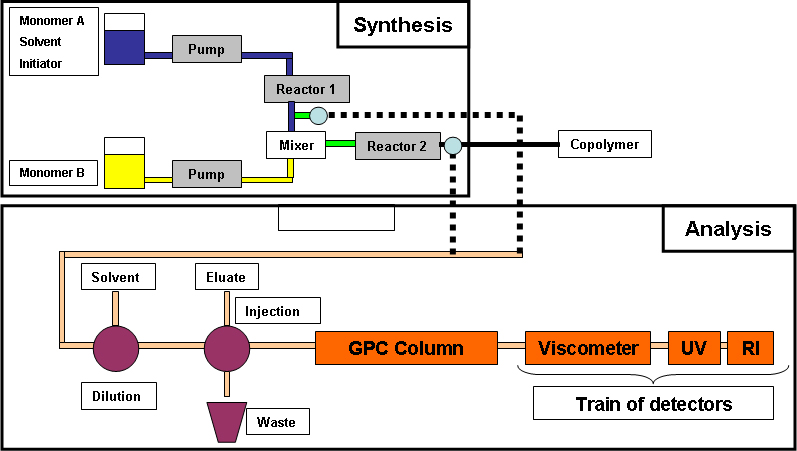

The CORSEMP system, manufactured by Polymer Laboratories Ltd (Church Stretton,

UK), is a customized high temperature GPC/SEC instrument. The column oven, which

can be operated from 30 to 220°C, contains two 6 port, 2-position sampling

valves, a 4 port multi-position detector selector valve and a 10 port 2-position

sample injection valve in addition to the three detectors; a refractive index

detector, a UV detector and a single capillary viscometer. The valves, the separation

column and the detectors are serviced by three high pressure liquid chromatography

(HPLC) pumps.

Sampling valves 1 and 2 discretely and alternatively capture polymer samples

from reactors 1 and 2 respectively, while pumps 1 and 2 dilute and transfer

these aliquots to the respective injection loops on the injection valve. When

the diluted polymer samples are present in the respective injection loops, they

are injected into the flow stream of the chromatography system, separated by

SEC, detected and analysed using viscometry, UV and RI detection. The whole

system is controlled and automated by a single software package which allows

continuous sampling and automatic analysis.

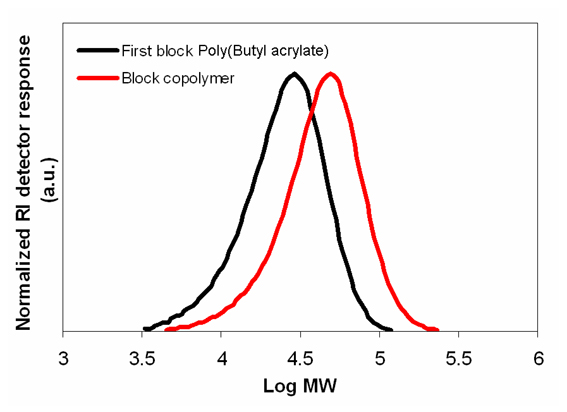

MW and MWD determination:

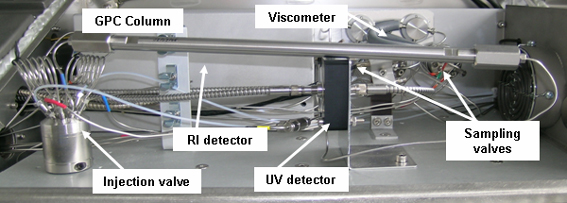

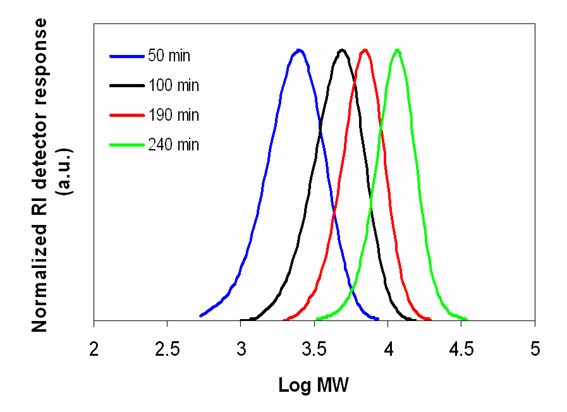

The GPC column coupled with the train of detectors can provide not only the

molecular weight of the polymers but their molecular weight distribution as well in about 12 minutes or less.

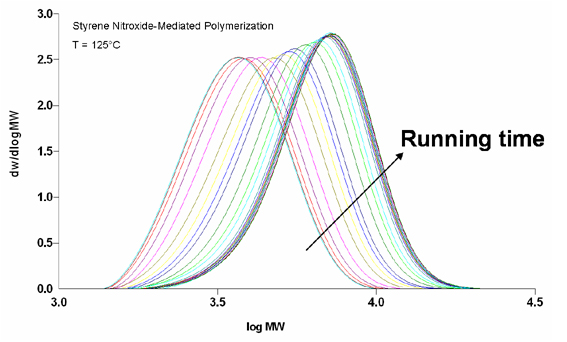

Reactor dynamics:

A continuous reactor is characterized by its dynamics e.g. the time required to reach its steady-state or the period of the transient regime after the modification of at least one parameter of the reaction (temperature, residence time, concentrations…). By monitoring the polymerization reactions in near real-time, one can determine the transient regime of the reactor as well as the time needed to reach the steady-sate.

Serial HTE:

Obtaining molecular weight and molecular weight distribution information during the polymerization process can help to understand and ultimately control the process or to rapidly get access to polymer libraries. Traditionally, key variables such as temperature, residence time and solvent ratios are modified systematically in batch mode using a single reactor or an array of reactors. However, these investigations are time-consuming and only describe the final product of the reaction. On the contrary, the CORSEMP system allows for rapid continuous analysis of the influence of stepwise or possibly continuous modifications of operating parameters.

Selected papers:

- Bally F., C. A. Serra, C. Brochon, N. Anton, T. Vandamme, G. Hadziioannou, A continuous-flow polymerization microprocess with online SEC and inline polymer recovery by micromixer-assisted nanoprecipitation, Macromol. React. Eng., 5 (11-12) (2011) 542–547 (invited article).

- Rosenfeld C., C. Serra, S. O’Donohue and Georges Hadziioannou, Continuous Online Rapid Size Exclusion Chromatography Monitoring of Polymerizations - CORSEMP, Macromol. React. Eng. 1 (5) (2007) 547-552.

Download posters: